My dad is working and my mom is using that loud monster that sucks things off the floor (I HATE that thing) so I snuck in here to pen my thoughts to all of you. Its been some time and I need to make sure that they are telling the whole story for all of you.

So, what's been going on? Back in May, I got to go to Norfolk with the ship. It wasn't too long of a trip...I'd say it took us about a year to get there, and we were there for like 6 hours (but I can't really tell time, so who knows). This was a first for me, as it was the first cruise that I've worked, which was pretty cool. There were a LOT of people on my ship, and that's the truth! It was a pretty neat experience and people seemed surprised to see a dog on the ship. Why is that?!? Lots of people tried to get their picture taken with me, so I will admit, It made me feel like a celebrity dog, like maybe Lassie, or Beethoven or Tramp (in Lady and the Tramp).

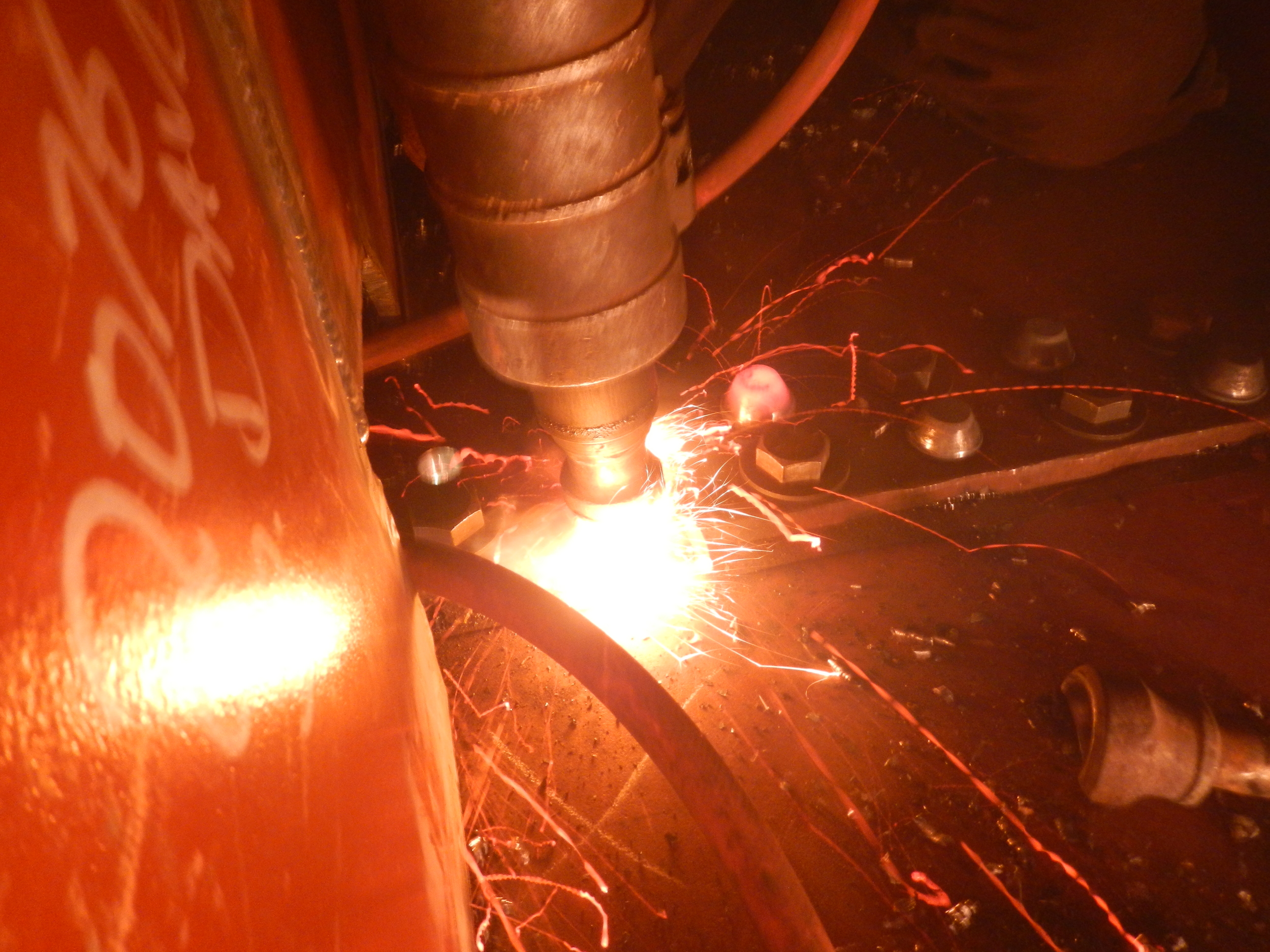

Then came the warm weather. I was told that they were busy this summer, painting the ship and doing lots of work and that it was dangerous for me to be on board the ship, but then I find THESE pictures on my parents drive... I'm not so sure what was going on, but some of it looks like monkey business was happening without me. I tell you, do I have to DO everything around there and supervise everyone??? These people also apparently know how to make messes!

I had to do some dog-subliminal-messaging with the Captain, to let him know that things needed to change, and wouldn't you know it? It worked... he told me that I could go to New York City on the ship. This trip was a bit longer and it was pretty hot, too. I was the first one off the ship, and I had to leave my mark on the pier. Let's say that my bladder must have been waiting for dry land, because people on the pier actually started clapping and cheering me as I was going to the bathroom. Yep, I was blushing. What? You don't think that dogs blush??? Well, I do!

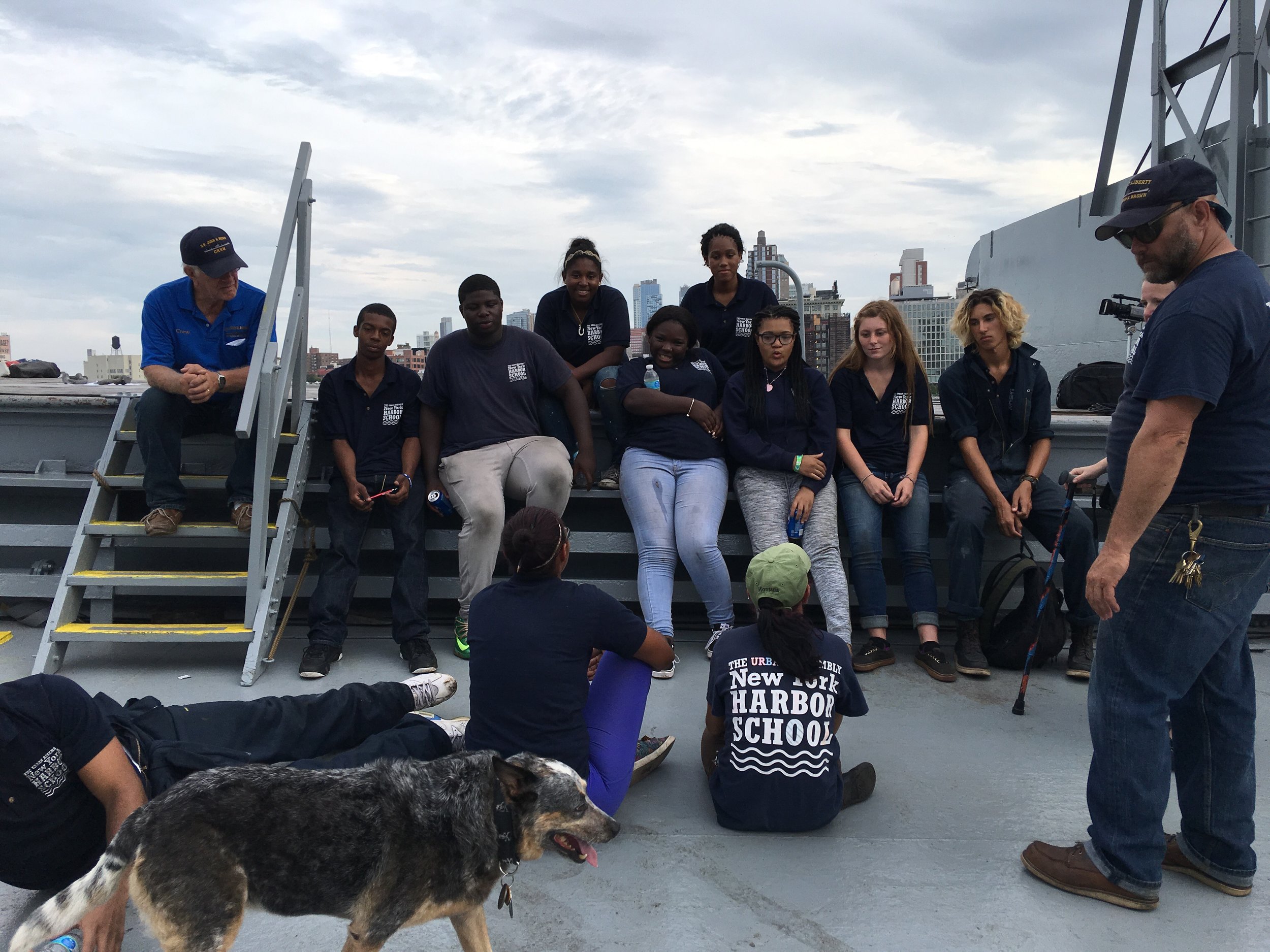

It was a neat trip and I got to hang out with lots of my favorite people. The kids from New York's Harbor School were fun to hang out with too. And then wouldn't you know it... I somehow hurt my paw. They babied me each day but finally, midweek, my dad brought me to a nice vet clinic in Manhattan and they gave me medicine to kill the bad stuff that was making me sick, they wrapped my paw nicely and they gave me pain medicine and a very horrible cone of shame. That thing... ugg {insert whole body shake and shiver}, THAT lasted all of one afternoon, until I convinced them that I was NO idiot and was not going to take off the bandage. People! Jeesh, its not like I'm dense...I get it!

But other than that, I got to hang out in New York City, and I saw the Statue of Liberty. I slept on the floor with the Captain half the time (not ALL my doing, his wife asked me to keep him company since he would be missing her), and the other half with my dad. Sorry dad, but someone's got to hang out with the Captain and it's my job. Here are some of the pictures I could find to show that I was there. I'm just glad they didn't think to take a picture when they picked me up and put me on the surgery table to look at my foot, before deciding to take me to the vet. That was embarrassing, for pete's sake.

Finally, this past weekend, we held our holiday party for crew members. It's always good to hang out with all my peeps, especially when they're not covered in paint and smelly grease. Plus everyone dresses up nice and they smell good. And don't tell my dad, but they also gave me food. AT THE TABLE, when my dad wasn't watching. Hahaha...

These people writing the blog have been busy, so i'm sure they wont mind that I jumped in here to get the job done. Hopefully I'll have more to tell you soon. Until then, stay away from cats (they are mean and think they're better than everybody else!) and buy lots of treats for dogs (like me...hint, hint, hint...)

~Jack (from the SS JOHN W BROWN)

Project Liberty Ship, Inc is a 501(c)3 non-profit, all volunteer organization engaged in the preservation and operation of the historic ship JOHN W. BROWN as a living memorial museum. Gifts to Project Liberty Ship are tax deductible.