Read this week’s blog on our popular and sold out second Steam School aboard the SS JOHN W BROWN

JOHN W BROWN Inaugural Steam School

The John W. Brown hosted its’ first Steam School on May 3-5, 2019. Organized by the engine department, 14 guests (and now members) were aboard for seminar’s on various aspect of the ship, and its’ machinery plant. This was followed by hands-on operation of the machinery, lighting off the engineering plant, raising steam, and operating the main engine and deck cargo winches on steam. The guests were provided accommodations and meals by the Stewards’ Department during their stay.

So what is the inside story?

It all started one workday (isn’t that how every great sea story goes?!?) in October 2018, at lunch in the mess, when crew member Greg was reading a magazine which had a listing of Steam Schools offered by various organizations, most of which were focused on antique farm and industrial equipment. Greg thought that the ship could do something similar, but he hesitated, because he knew if he presented an idea, he would own it and be charged with moving the idea forward.

After some deliberation Greg went for it anyway and he threw the idea out to fellow engineering department members and conversation ensued. Everybody jumped on the idea, and started brainstorming how the ship could host a steam school. We have a really big steam engine, don’t we? He ran the idea by the Chief Engineer, Joe Cadden, who agreed with the concept, and added “let’s put steam on deck.” Normally we use air on deck and we had not put steam on deck in years.

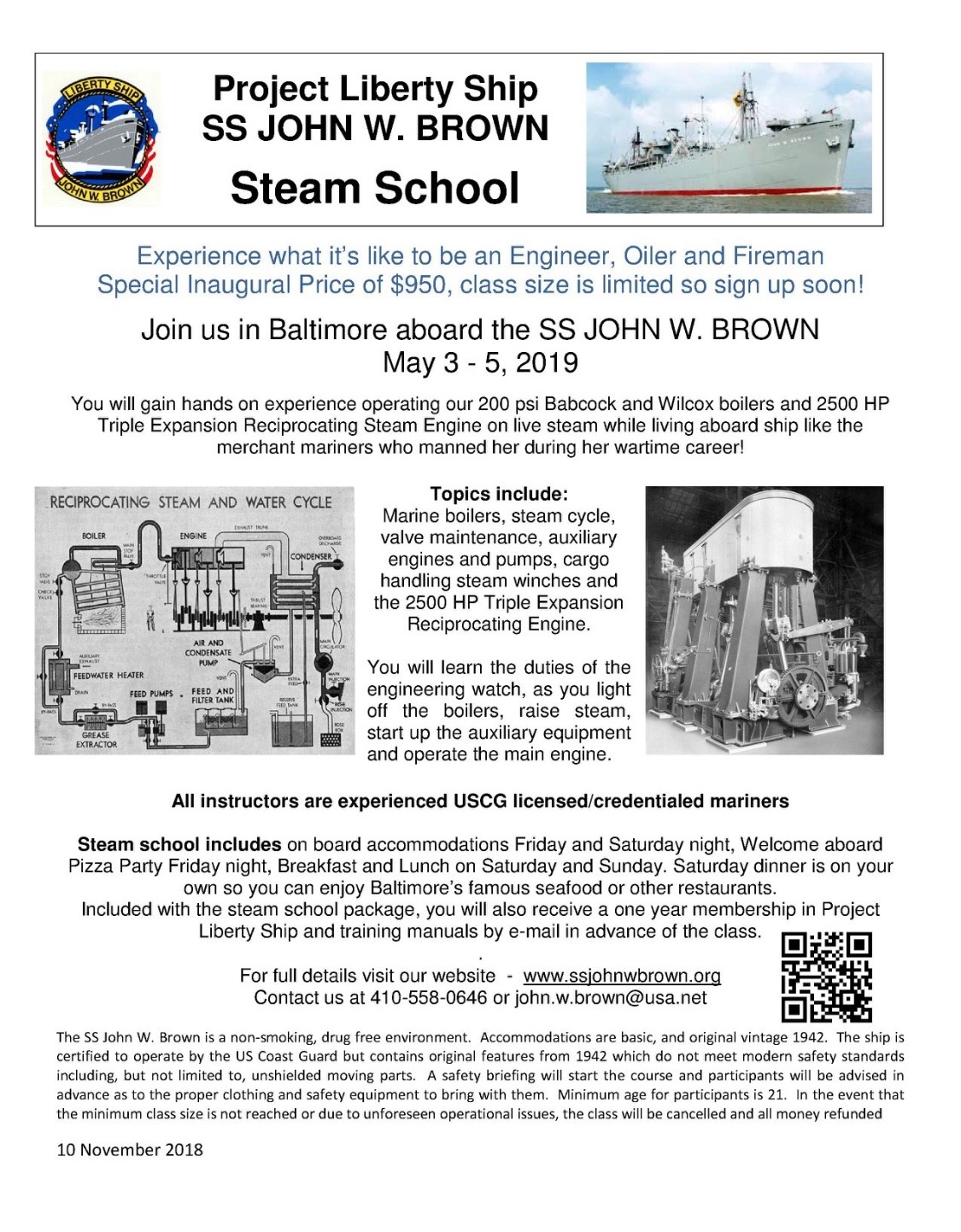

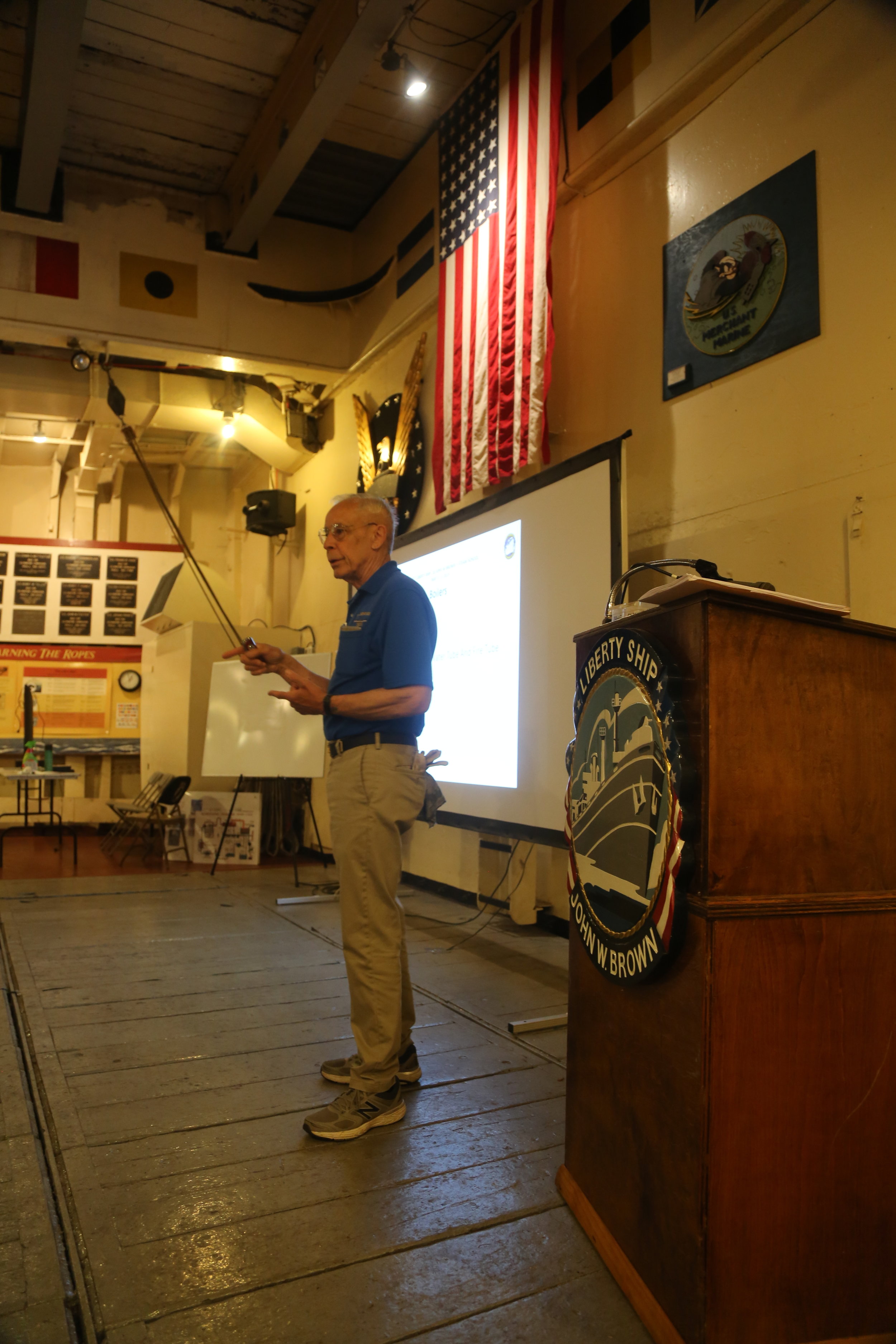

More lunchtime conversations followed. How many guests, how long, when, accommodations, what topics, how much classroom time, who would instruct, and other ideas. Finally, Greg prepared a concept proposal, outlining the proposed Steam School, and the proposal was presented to the Board of Directors by Joe Sargente in October 2018. It was quickly approved, with only one comment- “Why didn’t we think of this earlier?” Now that the concept was created and approved by the Board of Directors, it was time to market the concept. Was there a market for steam school?

After a few trials, Dick Sterne developed a flyer, and it was approved by our PLS President in early November 2018. We were anxious to see if we could sell our concept. One engineering team member spilled the flyer onto the internet… and the ship’s phone started ringing…

When the ticket sales went live in late December 2018, the minimum class size was sold in one weekend. In three weeks, the class was sold out at 14 guests. We never got a chance to market the school. The ship’s phone continued to ring. Quickly, a waiting list was developed. Whoa! It seems we had something here. There was a market for steam school!

An agenda was developed and volunteers from the engineering department were solicited, roles identified, and roles assigned. Lead instructors, assistant instructors, licensed/credentialed watchstanders, and supporting staff were all needed. Greg became the self-appointed director (and chief delegator).

The guests would be staying aboard the ship. It quickly became evident that the Steward’s Department was crucial to the success of the Steam School. Commitment from the Steward’s Department was obtained, and Mike Schneider agreed to be in charge of the guest accommodations.

In the final two weeks, the guest binders were printed and available. Cleaning needed to be done because the members wanted to make sure that a good impression was made. This involved…Cleaning the rooms. Cleaning the heads. Cleaning the engine room. Cleaning the saloon. More cleaning. Greg made the pitch that the ship was in the hospitality business now. Much to his amazement, nobody laughed at the idea (at least not openly) and by the time guests arrived, mints had been placed on the guest’s pillows.

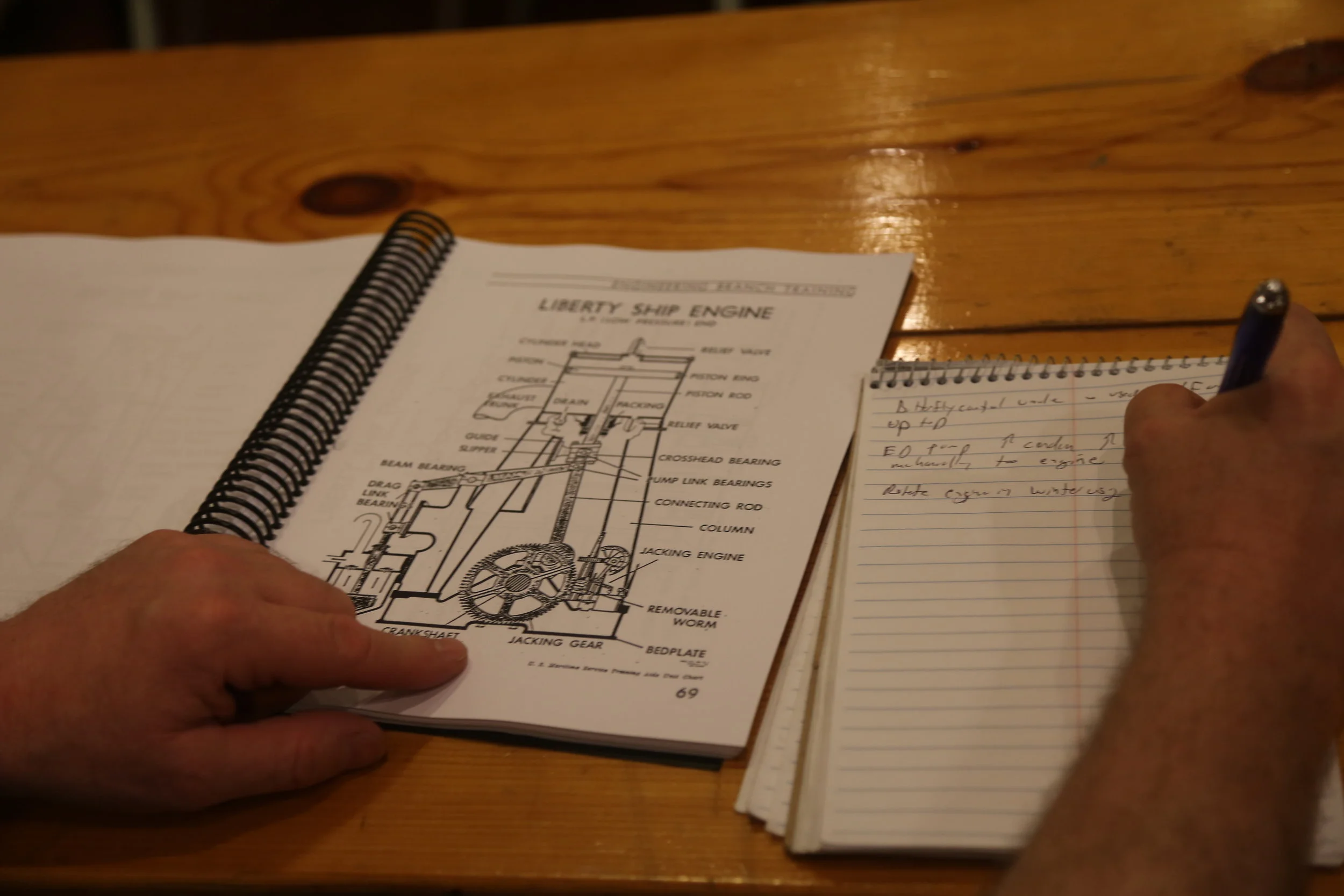

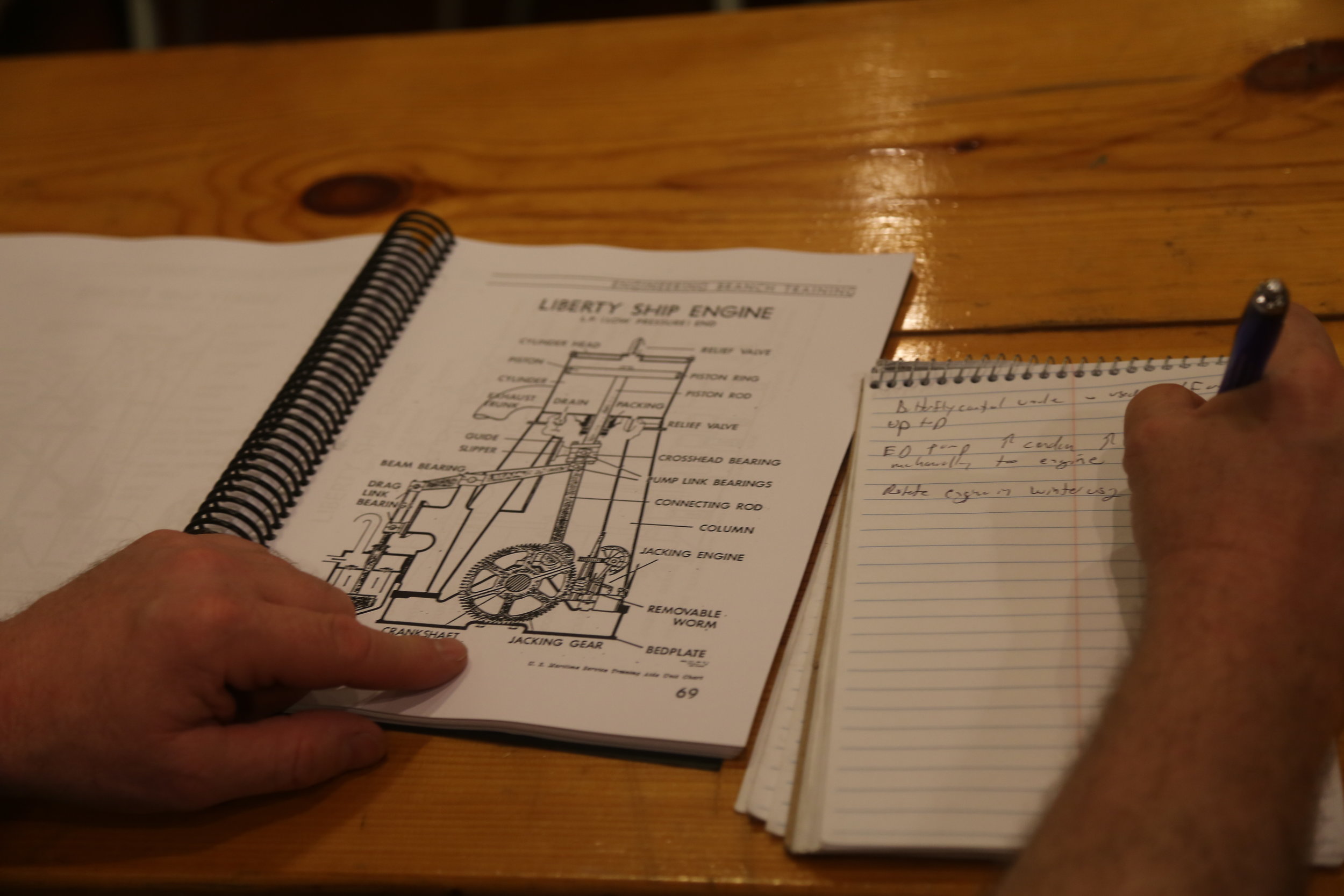

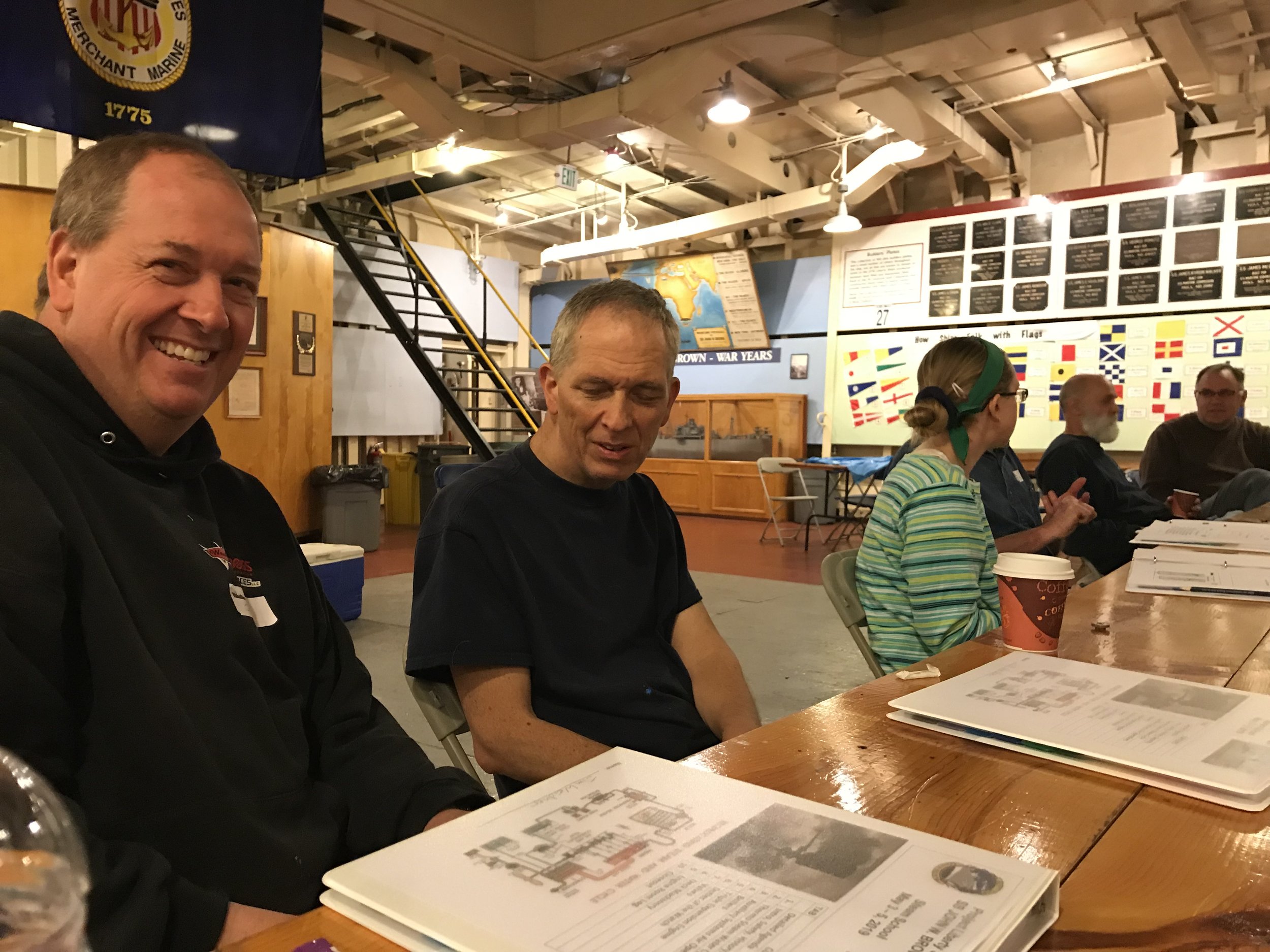

On May 3rd our crew members assembled to greet the guests and welcome them aboard. Students were checked in and shown to their room. Each guest was presented with a binder (with copies of all slides and handouts), a monogramed rag, JWB pen, tee shirt and water bottle. Lunch was provided and once everybody was settled, the school started at 1300 with introductory remarks, then a discussion of thermodynamics, the steam cycle, auxiliary systems, and finished the day by providing our guests with the opportunity to operated three pieces of machinery in the engineroom on compressed air. After a dinner provided by the Steward’s Department, the evening was completed with a ship’s tour.

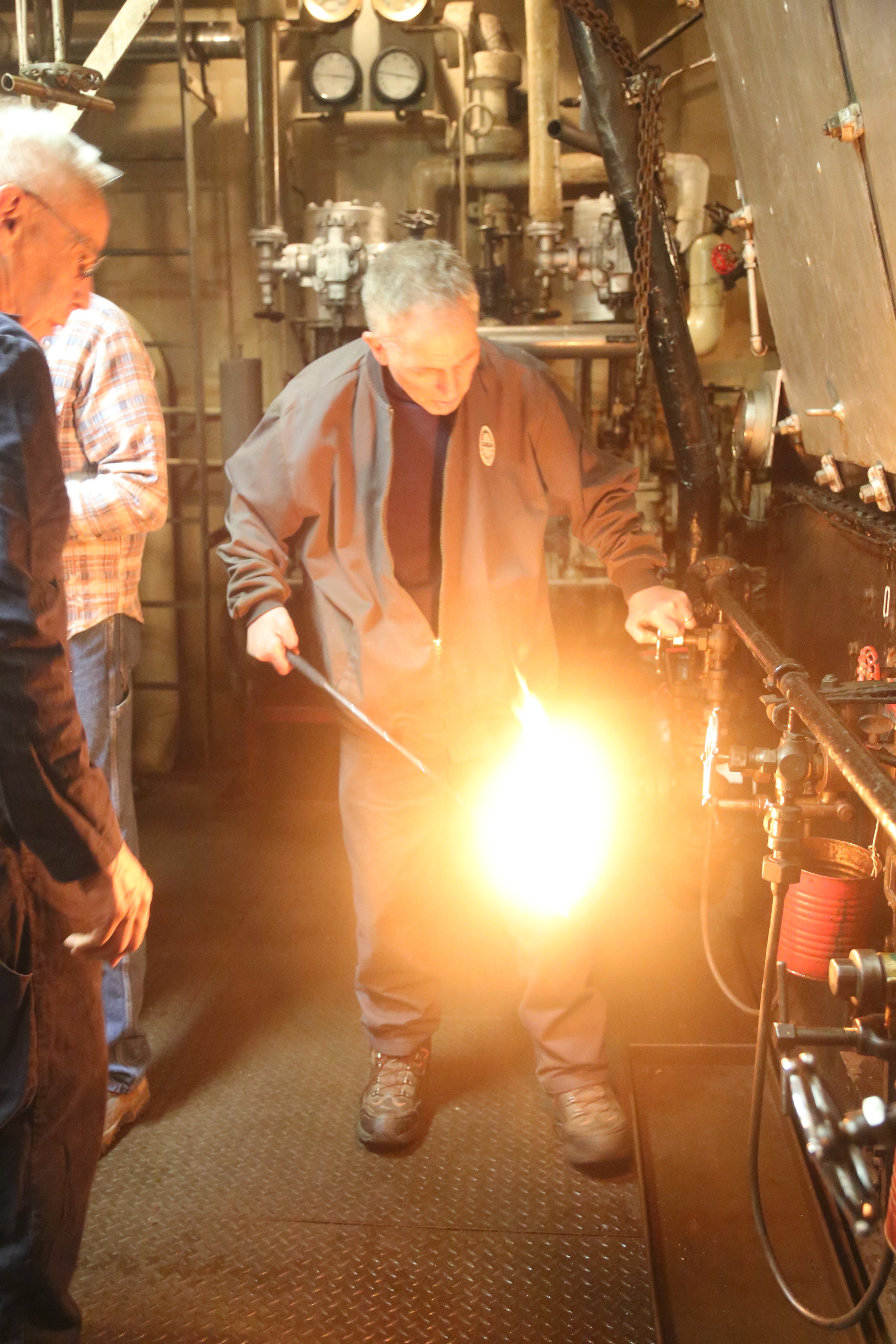

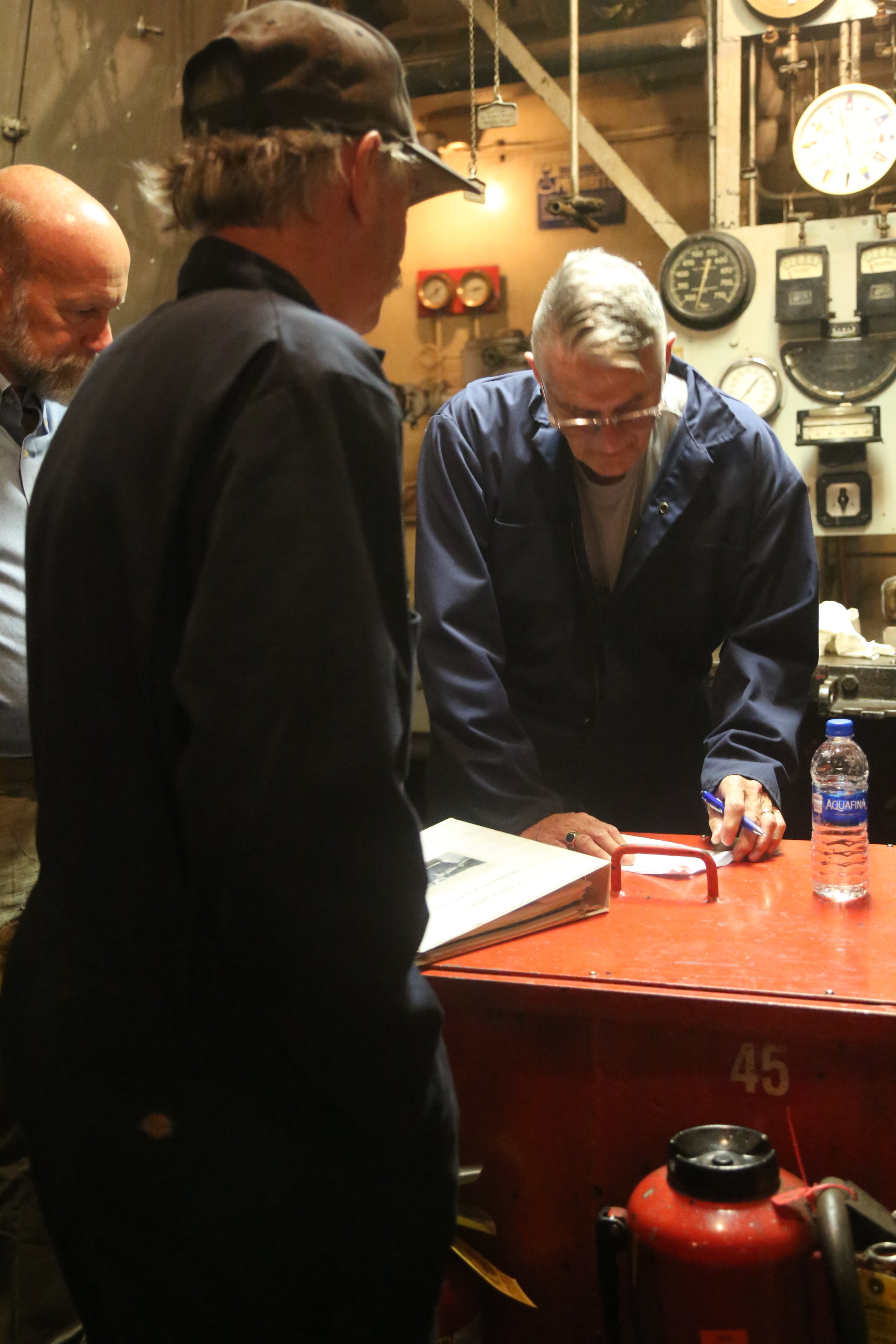

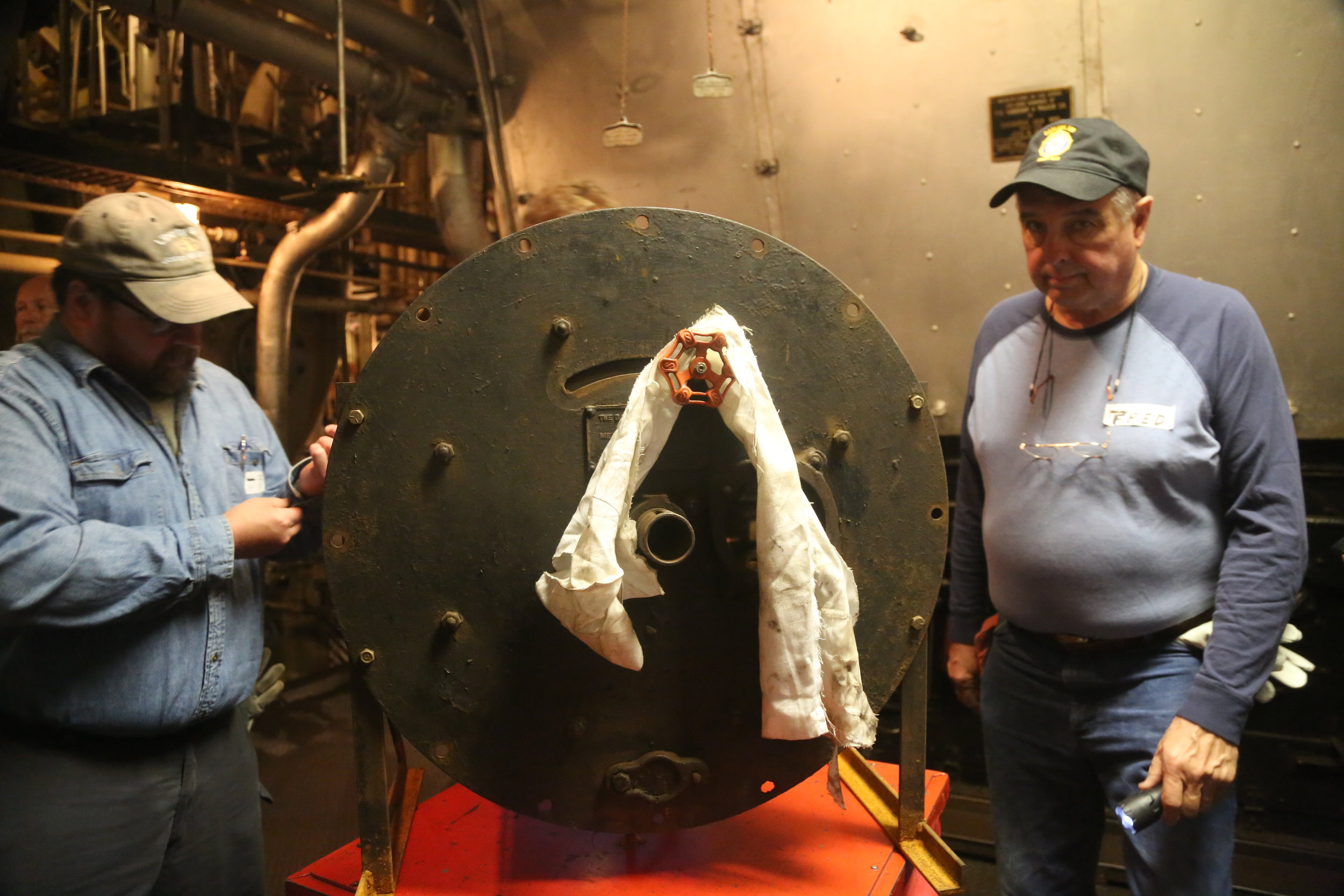

Saturday, May 4th was filled with technical sessions all day. Boilers, and Reciprocating Steam Engine were the topics of conversation and everyone got to light a fire in the boiler. Discussions on how to stand watch followed. The technical sessions wrapped up with disassembly and overhaul of a valve.

Lightoff came early at 0500 on Sunday, and steam was raised. Once operating pressure was obtained in the boiler, the auxiliary plant was started up, and the steam cycle was complete. The guests were split into two groups, one group one deck operating cargo winches on steam, and one group in the engineroom, standing watch with the boilers, main engine and auxiliary plant.

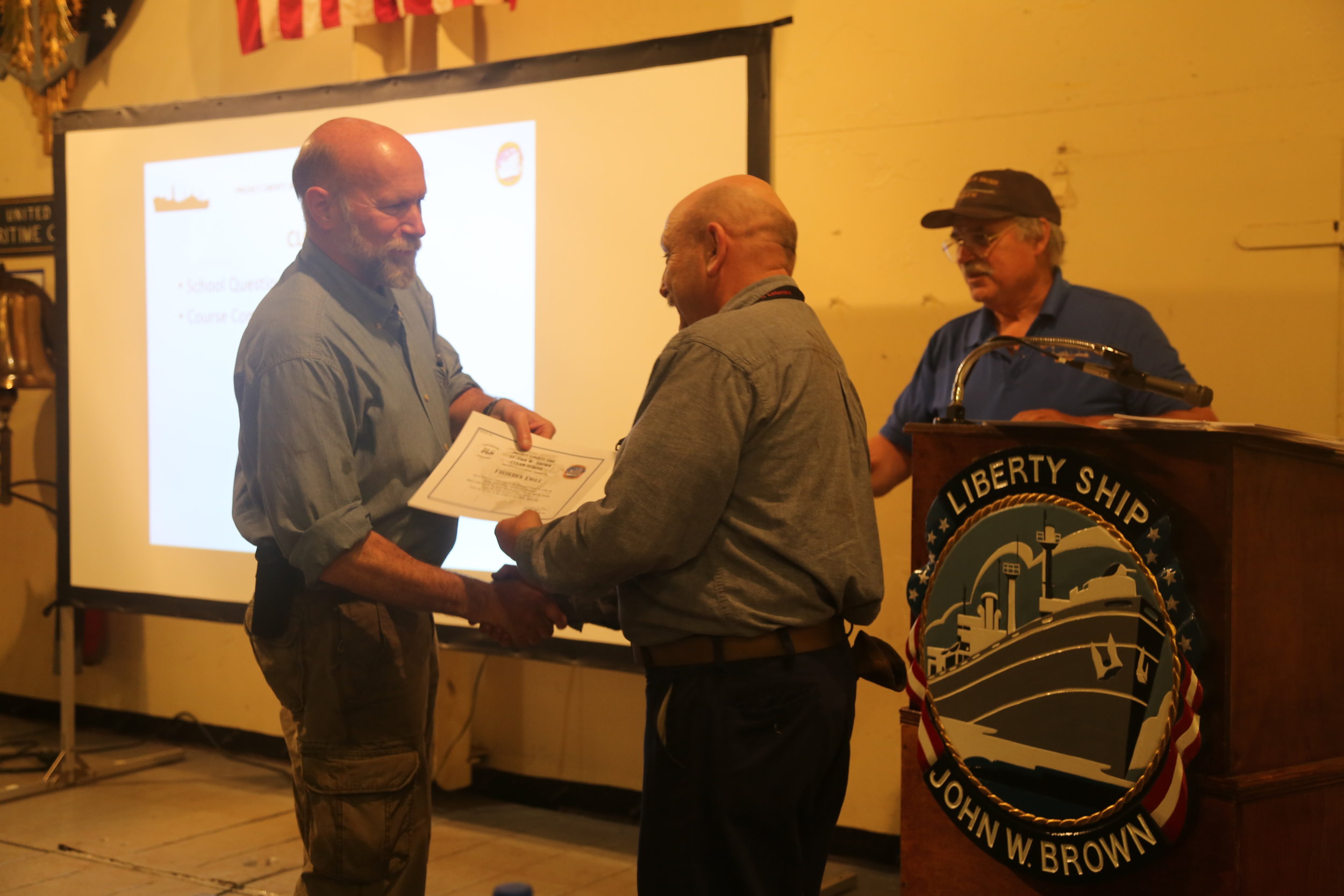

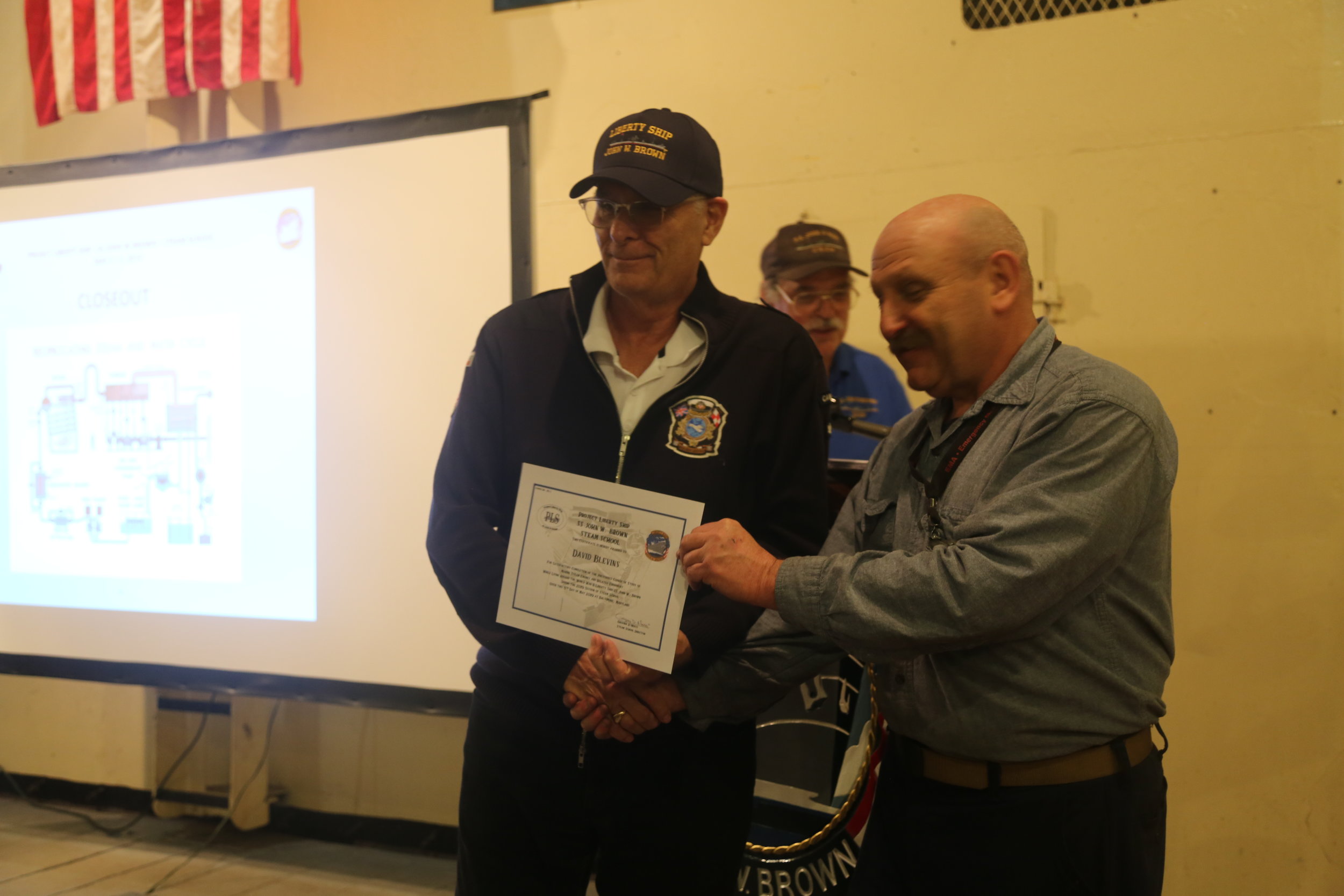

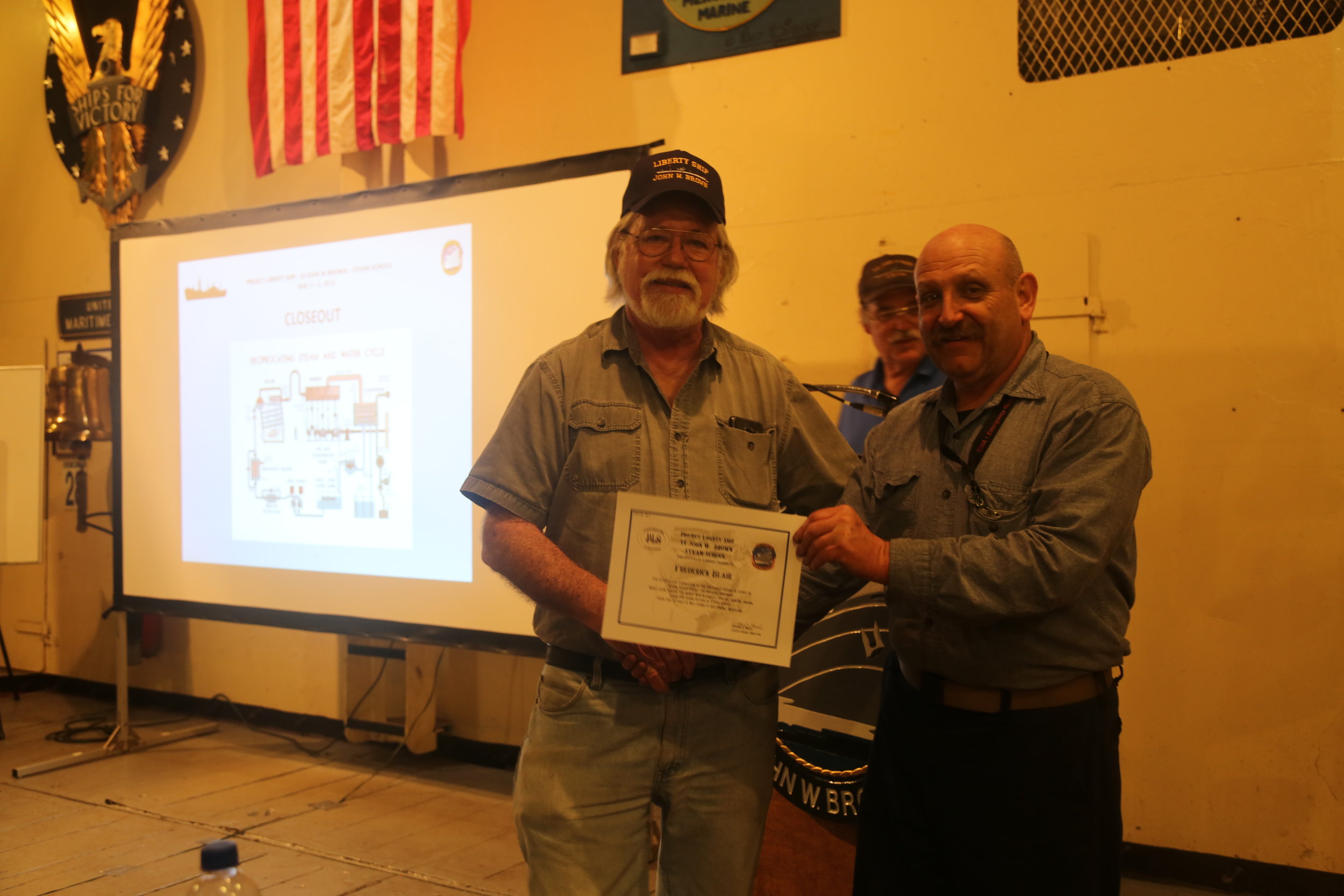

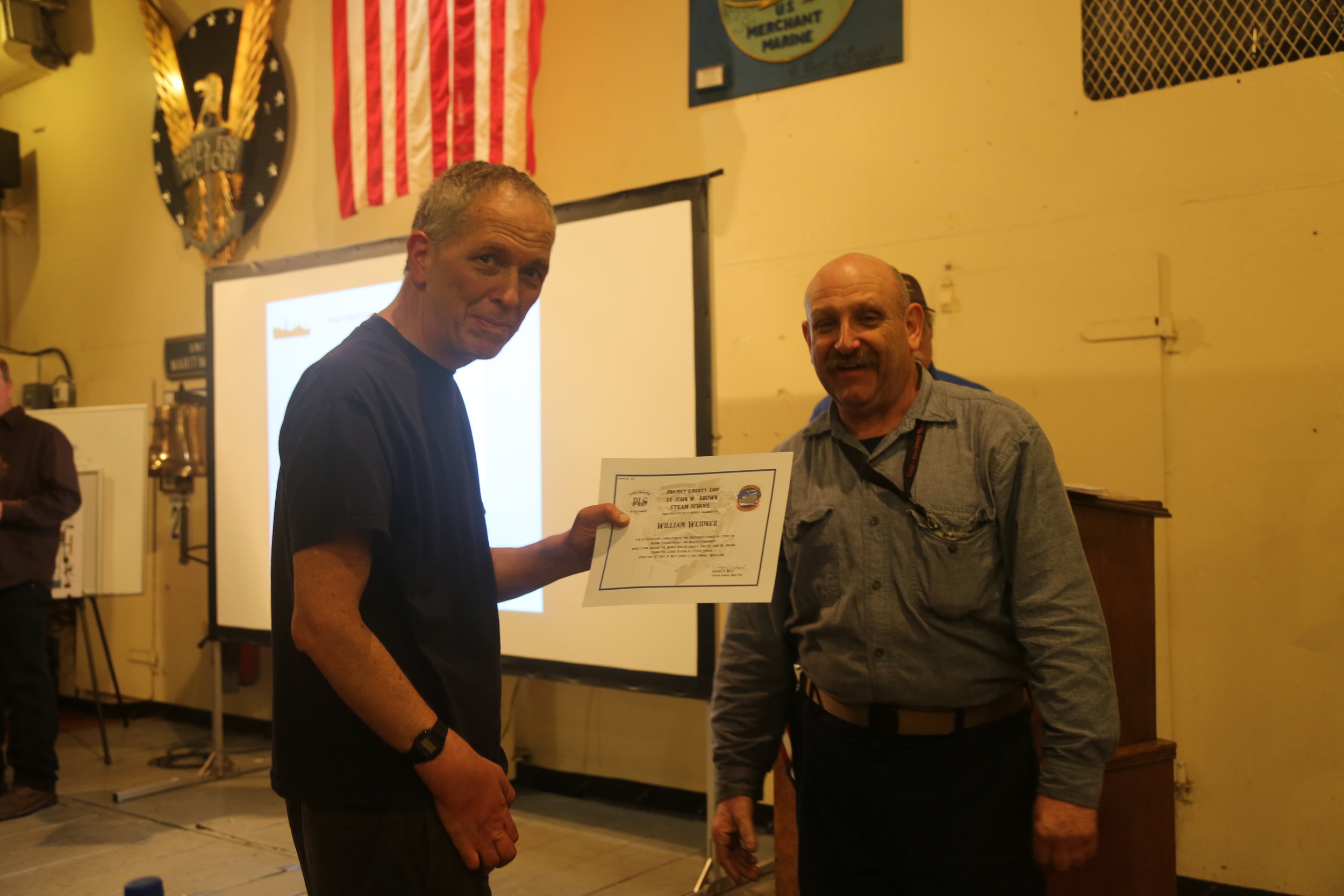

Two of our guests were crew members/staff from the SS Keewatin, a museum ship located in Port McNicoll, Ontario, Canada. At the Steam School closeout, hats and pins were presented by Mr. David Blevins of the SS Keewatin, to our instructors, chief engineer, and the school staff. We were surprised and grateful for the token of appreciation.

Finally, group pictures were taken and goodbyes were said. Participants

Steam School was a success and comments and reviews by participants yielded great comments and some suggestions for future steam school. Keep an eye on the website and Facebook for information on the next steam school which will be held November 8-10th. We are gearing up for our first cruise of the season (tickets for the June cruise can be ordered here until June 1st (promo code PLS2019 for a discount), but after that we will start to promote Steam School #2. Until then, stay safe and keep supporting Project Liberty Ship.

Valve Maintenance

Valve Maintenance – A never ending task aboard ship

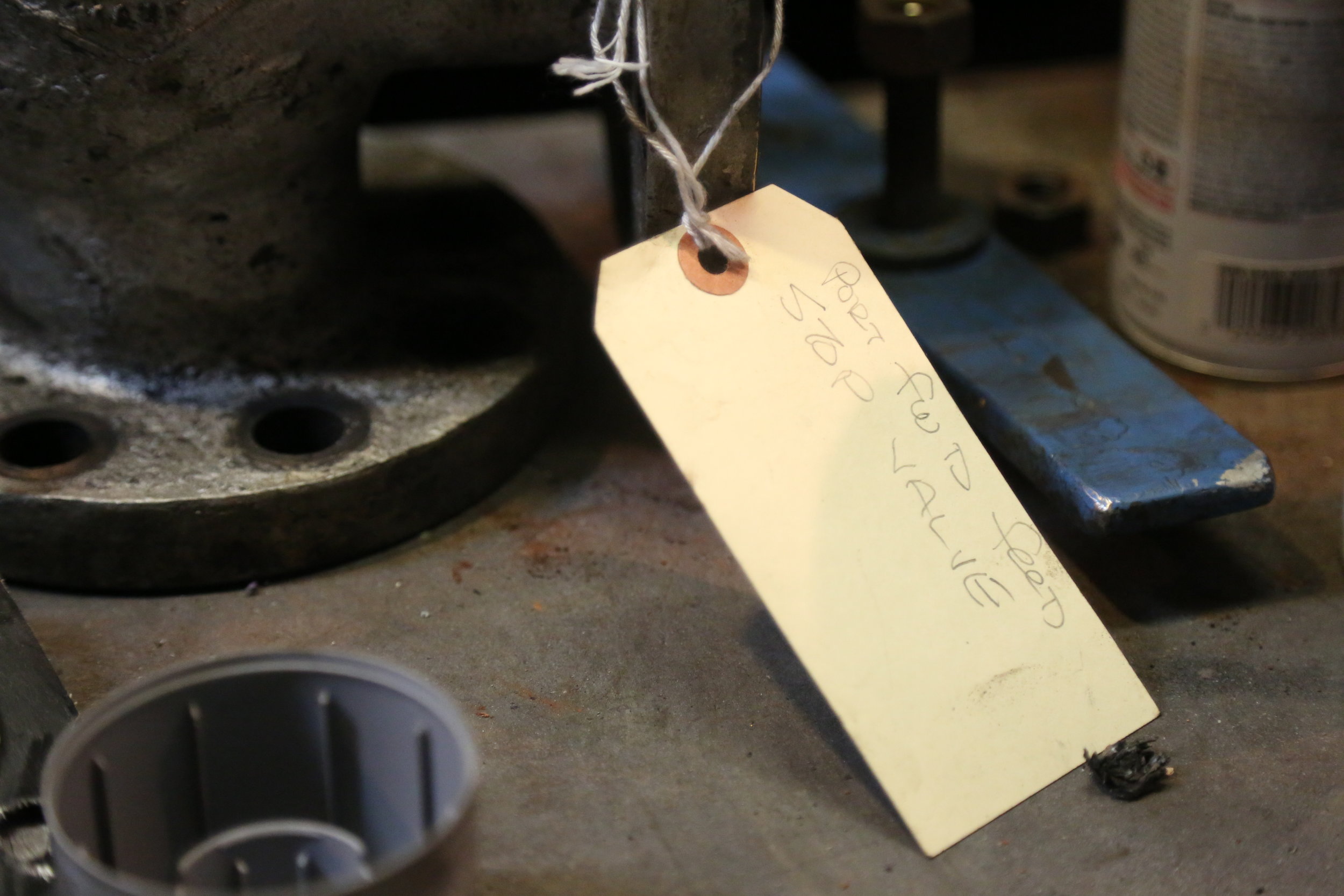

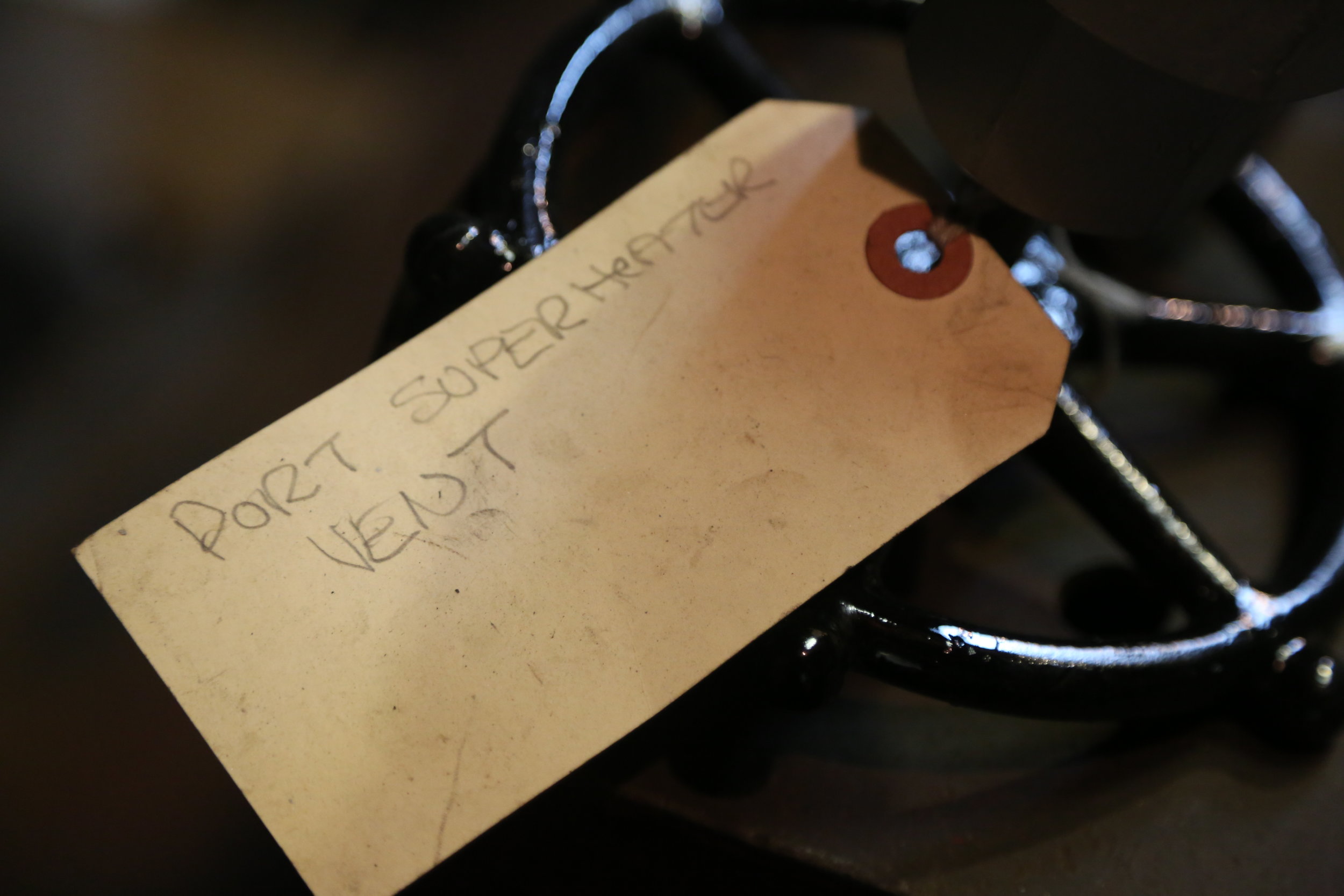

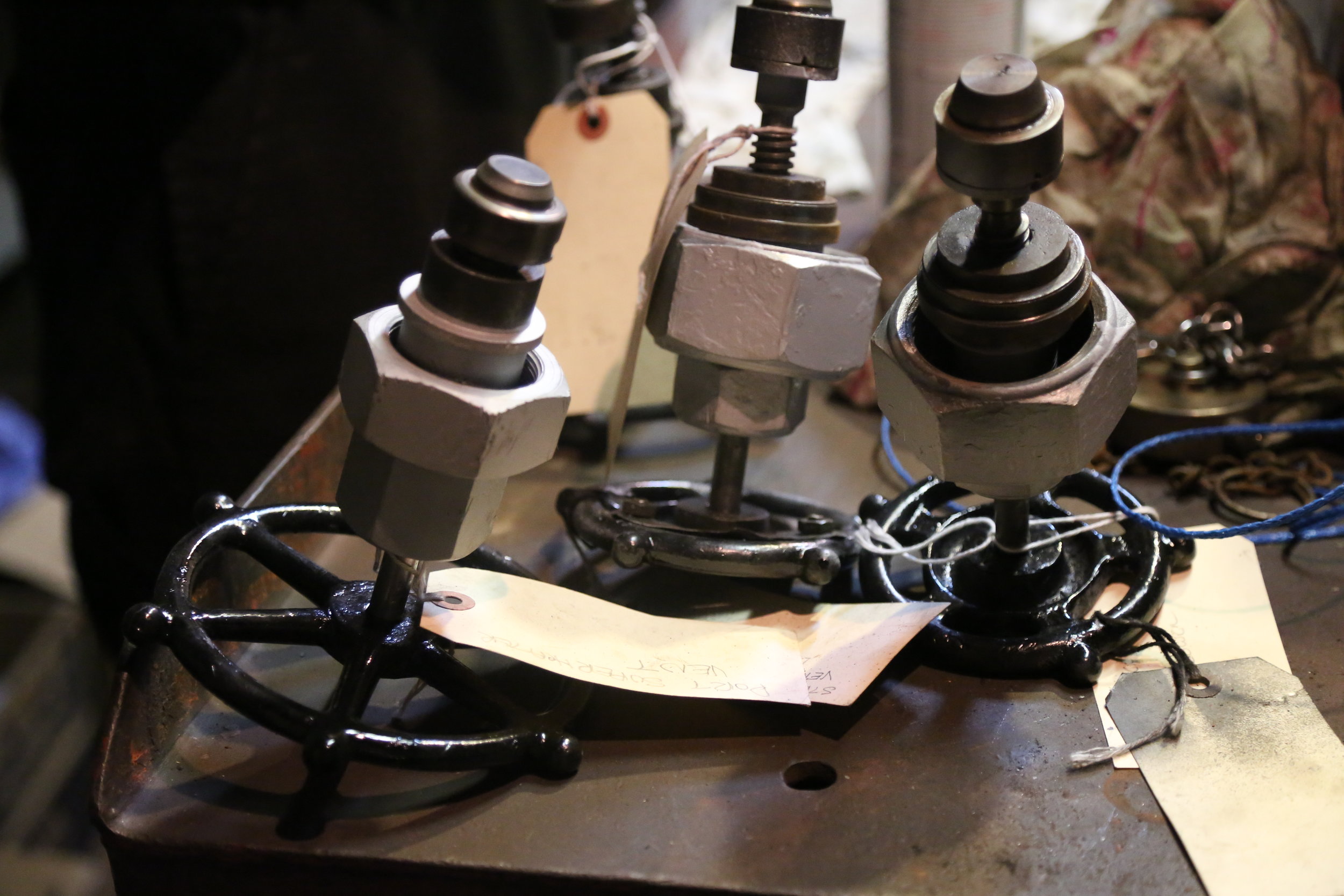

Hundreds of valves are present in the piping systems found on Liberty ships to control and direct the flow of fluids and gases, including steam, that are part of the ship’s engineering systems. The proper operation of these valves is essential for the safety and efficient operation of the engineering plant. A system of regular inspection, maintenance, and repair is necessary to ensure the valves operate as designed and this is included as a normal part of the ship’s work schedule. In other words, we'll be having some Coast Guard Inspections soon... :)

Most of the engineering maintenance on JOHN W. BROWN is scheduled during the winter months when the ship is not steaming to conduct Living History Cruise and port visits. This year’s valve maintenance effort is focused on the boiler-mounted valves. These are valves located on the boilers or are the first valve from the boiler on a system connected to it and is subject to full boiler operating pressure (~200 psi for a Liberty ship). Coast Guard requirements call for these valves to be removed from the boiler at periodic intervals for inspection and that milestone occurs this winter.

The valves are completely overhauled for the inspection. This includes disassembly of the valve, cleaning the individual components, lapping the mating surfaces of the valve disc and seat to insure the valve doesn’t leak when shut, replacing the packing around the valve stem to prevent leaking around this part of the valve that is turned during operation, and replacing the gaskets where the valve is connected to the flange of adjacent piping. If a part is found to be defective, it is repaired or replaced. In addition, all the hardware used to secure the valve to the adjacent pieces of the piping system is being replaced with studs and bolts that are rated for the temperatures and pressures present in the system.

Volunteers have removed the first 16 valves and have begun overhauling them to prepare for inspection. The valves include a range of sizes and designs. As work is completed on the initial valves, additional ones subject to the inspection will be removed and overhauled in the coming weeks. When the inspection is complete, the valves will be reinstalled on the boiler until the next inspection milestone.

This is just more proof that the work is ongoing and will never be done on the JOHN W BROWN. We are always looking for individuals that are good with their hands and willing to help out. And no experience is needed. Project Liberty Ship and our wonderful gray lady, is always doing on the job training in many different ways. On this specific day, there were men painting, grinding, disassembling, reassembling, making new gaskets, working with wire brushes and this was just in one section of the engine room. Thanks for reading and thanks for the interest in the SS JOHN W BROWN.

Project Liberty Ship, Inc is a 501(c)3 non-profit, all volunteer organization engaged in the preservation and operation of the historic ship JOHN W. BROWN as a living memorial museum. Gifts to Project Liberty Ship are tax deductible.