Having just lived through a record breaking blizzard it seems like a good time to talk about what happens on the other side of the pier. Tankers filled with road salt come and go with great regularity all year long. No sooner have the tugs brought them in and they've tied up then the giant bucket is bringing the salt up out of the hold. Dump trucks line up and move the salt across the street into huge mountains. When there's a snow storm in the forecast the salt trucks will lineup, fill up and drive back to their respective counties.

This is the berth right across from where we berth. That crane may not look very big in this picture but it's really huge.

There are some people in this shot to give a bit of perspective.

The tugs will bring the very full freighters into berth.

The dump trucks line up waiting for the fun to begin.

No time is wasted and as soon as the freighter is tied up the unloading begins.

Then the dance begins. Fill up, drive across the street, dump salt, back across the street and repeat and repeat and repeat.

These mountains of salt are all over the place in Canton.

You may wonder how they get that big. Lots and lots of work.

It only stays piled up until a storm is coming. When the forecast goes out the salt trucks line up to be loaded up.

You can see they come in all sizes and colors. This is just a small sample of the ships that come in filled with road salt.

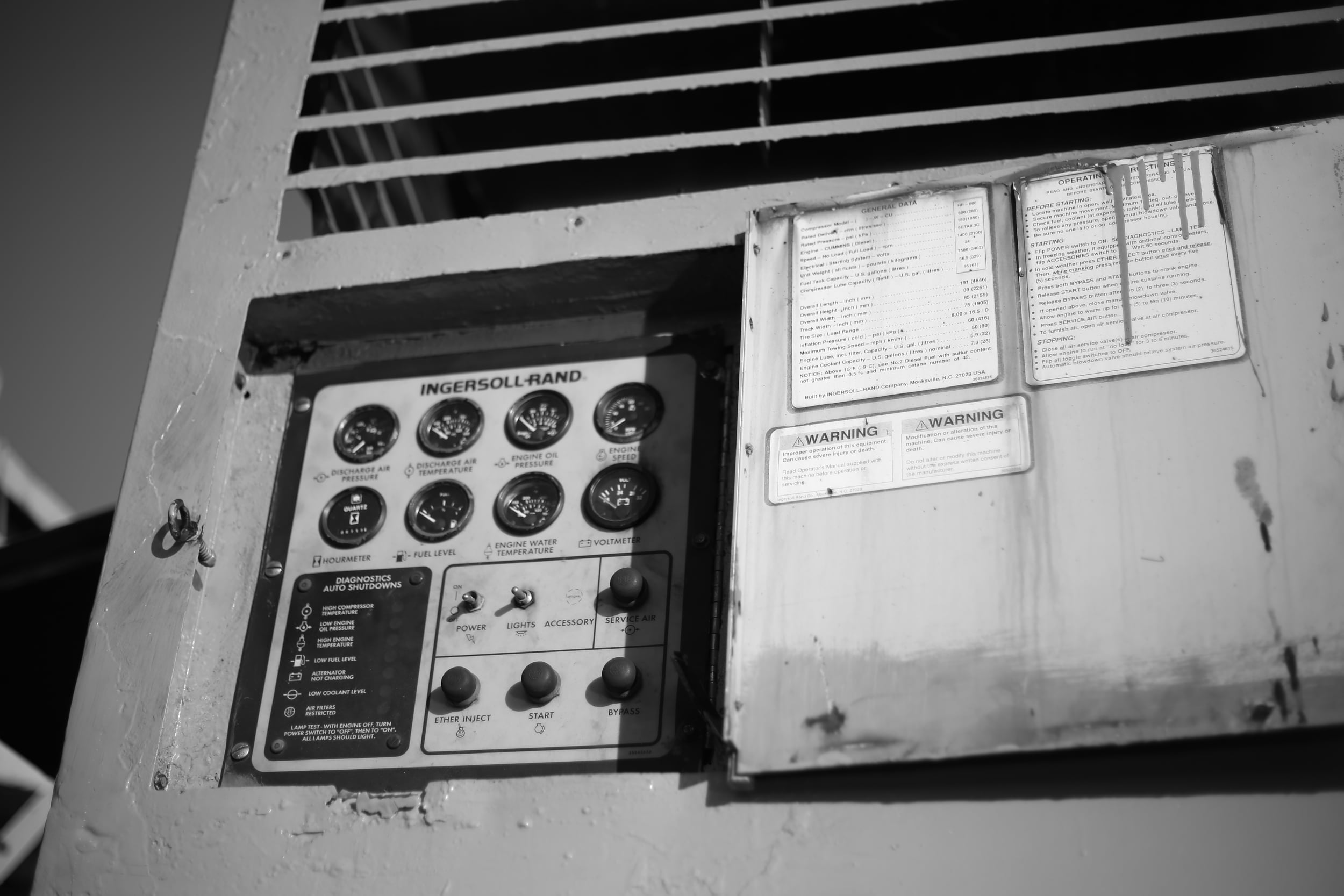

Project Liberty Ship, Inc is a 501(c)3 non-profit, all volunteer organization engaged in the preservation and operation of the historic ship JOHN W. BROWN as a living memorial museum. Gifts to Project Liberty Ship are tax deductible.