Riveting began with the first iron hulled ships in the early 1800's and followed on the way blacksmiths joined two pieces of metal together. As new technology was developed the process could be done by fewer men and more efficiently.

Liberty ships continued to be built with rivets after welding hulls had become more common. Skilled rivet teams were plentiful and welders were still learning their trade. Welding also came with problems of cracks and fractures. The riveted hulls of the Liberty Ships produced at the Fairfield shipyard did not experience any failures. The method used produced extremely strong hulls and the ships were in great demand even after the war for this reason.

The challenge to having rivet work done today is that there aren't many people who can do it. Beyond skill it takes strength and endurance. The rivet gun is heavy and most of the work is done facing upward on the bottom of the hull. A visit to the shipyard takes a great deal of coordination, and money. One way to raise funds for new rivets is to place old rivets in good homes. For a tax deductible donation you can own your own piece of history. Once you've read through the blog and watched the video you can CLICK HERE and send for your own rivet on a commemorative stand.

Our Rivets are available for a donation of $100. We invite all donors to pick them up on the ship on April the 11th from 11am to 2pm. We will offer light fare, VIP access to the ship and the ability to have a preview of some of the new parts of our Living History Cruises. If unable to attend April 11th, we will ship the rivets at that time to the remaining donors.

Here's a video showing the process of riveting the hull. This is our own JOHN W BROWN at Colonna's Shipyard this past fall.

Work begins in the plate shop. The steel plate has been cut to size and the holes are being drilled for the rivets.

The sized steel plate has been fitted into place on the ship’s hull. The butts of the plate are tack welded into place and the seams will be riveted. This arrangement gives the hull more flexibility and strength than an all welded hull.

This is a reaming tool. Once the two plate have been lined up this tool makes sure the holes for the rivets are perfectly matched and the same size.

The riveters will measure the thickness of the plates to be joined by the rivets. Here a rivet is cut to the proper size. The hull plates are thinner than the keel plate so it is important to measure.

The rivets are counted and arranged in the order that they will go into the forge.

This way the rivet team works seamlessly in getting the job done. It’s a six-man team so organization makes the job run smoothly and quickly.

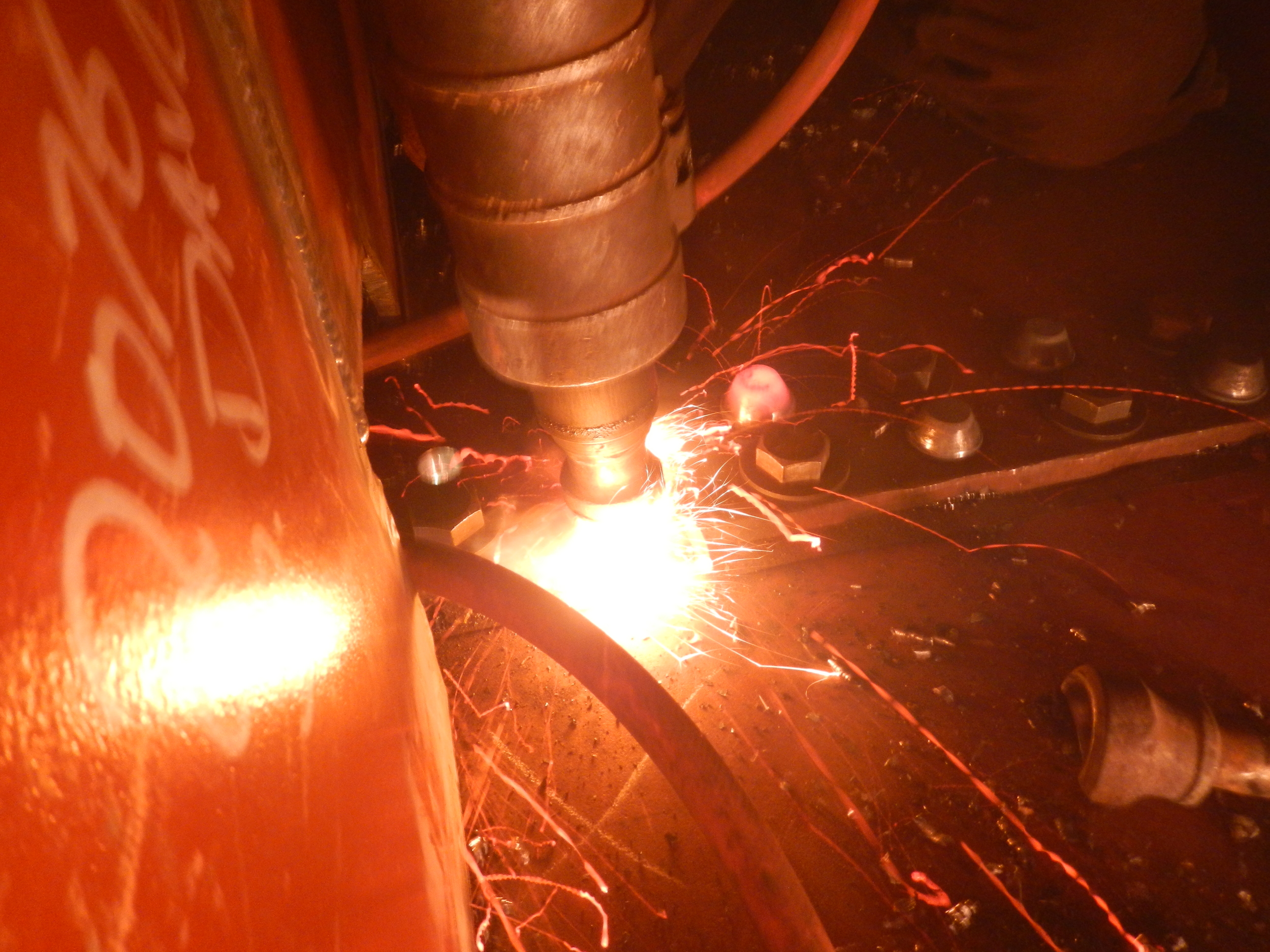

The rivets are heated to over 2000 degrees Fahrenheit in a kerosene-fired forge. This team member knows where the rest of team is in the process just by listening.

The timing for heating the rivets is crucial as there is a small temperature range to get the hot rivet into place and the end peened over.

You get a nice glow on a rivet at 2000 degrees Fahrenheit.

This is the pneumatic rivet gun.

The two plates are initially bolted to hold them into place. The riveters remove the bolts and replace them with rivets.

The bolts are placed in a W pattern. When the first set of rivets has been installed the bolts will be removed and the remaining rivets will be installed. The rivets are inserted from the inside of the hull. You can see the peened rivets on the right of the photograph and the empty holes on the left.

The rivet is held in place from the inside of the hull and the pneumatic drill peens it into place.

Seen above: The double bottom tanks of the BROWN do not offer a spacious work environment for the "Bucker." There are at least two men in the tanks at any time during the process.

This riveter is using a caulking tool to assure that the seam is watertight. This is not your ordinary caulking gun. It forces the edge of the outer plate tightly against the inner plate.

You can own your own piece of history! CLICK HERE to make a tax deductible contribution to the Rivet Drive. All contributions will go towards keeping the JOHN W BROWN in tip top shape and sailing for years to come.

Project Liberty Ship, Inc is a 501(c)3 non-profit, all volunteer organization engaged in the preservation and operation of the historic ship JOHN W. BROWN as a living memorial museum. Gifts to Project Liberty Ship are tax deductible.