Lately, we've been hearing about the Hawsepipe and Hawsepipers because one of our own has become a Third Mate this way. After the war, the BROWN was a Maritime High School in New York City for over 30 years. Since Project Liberty Ship restored the BROWN, we've kept the education theme alive in many ways. Some of our crew members started volunteering on the ship as kids and later attended maritime colleges, like:

Currently, one of our first STEM graduates is attending Norwich University The Military College of Vermont with another crew member attending the Great Lakes Maritime Academy. And there is another way: coming up through the ranks, or as they say, coming up through the Hawsepipe.

The Hawsepipe is the pipe that passes through the bow of the ship through which the anchor chain passes. The term 'coming up through the Hawsepipe' is an informal way of explaining in the nautical world, the way an officer of a merchant ship can begin their journey by starting as an unlicensed merchant seaman, then getting the sea time, the training and classes needed, and the on-board assessments to qualify for and test for a license as a Third Mate. Below is our very own Felix and his story.

Felix, in uniform. On one hand it seems like so long ago, but in some ways it feels like yesterday.

Felix and his oldest son

"It was always my dream to become a Merchant Marine, even as a child growing up in the province of Bohol, in my native country, Philippines. With a lot of hard work and sacrifices, I obtained my Bachelor of Science in Marine Transportation from the Philippine Maritime Institute.

In 1999 I started shipping out through a Japanese Company under the command of a Korean Captain, as a Deck Cadet in a log bulk ship for a 12 month straight contract. After that, I was given another assignment as Ordinary Seaman in a Car Carrier until promoted to Able Bodied Seaman. As AB, I gained a lot of sea experience on board various vessels and worked with people of different nationalities.

I immigrated to the US in September of 2006 through a petition by my wife. Unsure of which career direction to go, I initially worked as a Maintenance Mechanic in a hotel before I decided to pursue my original dream. It was in 2011 when I finally got my Able Bodied Seaman Unlimited here in the US. It would not have been possible for me to complete all required sea time without the help of the JOHN W BROWN.

Two friends, Percy and Bien, convinced me to volunteer on the BROWN. I joined and started working on this historic ship in 2010. I met many people who have shared their amazing stories during the time I've been volunteering on the Liberty Ship.

AB Felix at the wheel on the BROWN's flying bridge in 2011.

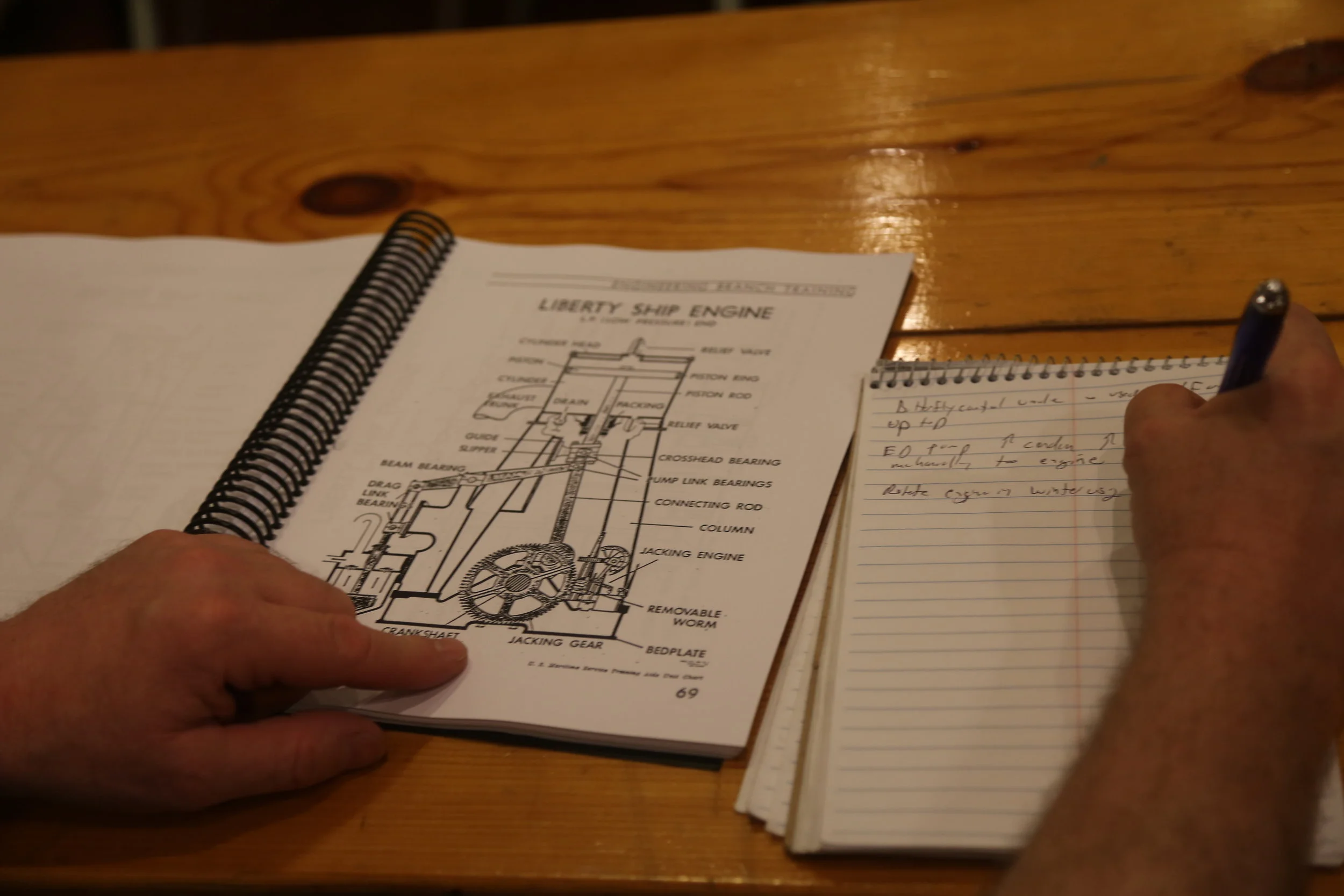

I joined the Seafarers International Union in 2011. Since then, I've gained numerous experiences in American Fleet vessels. I later developed an interest in becoming an officer, so while working on board, I began reading study guides for deck officers.

Studying and preparing for the Coast Guard exam for my Third Mate Unlimited License was very challenging. Around the time that I was self-reviewing for the test, my wife delivered our son Daniel and we also moved to our new house. Through the love and support of family and friends, my own commitment and dedication, and the help of my old notes, which I've kept for a long time, I recently successfully passed the exam. Thanks to God."

~Feliz S. 2/7/2015

Above: Felix and his son working on the gun.

Felix and Bien on deck. Bien was one of the people who was instrumental in Felix becoming a member of the ship.

General ships meeting. Pete and Felix (in the foreground).

Project Liberty Ship, Inc is a 501(c)3 non-profit, all volunteer organization engaged in the preservation and operation of the historic ship JOHN W. BROWN as a living memorial museum. Gifts to Project Liberty Ship are tax deductible.